Mga Tampok

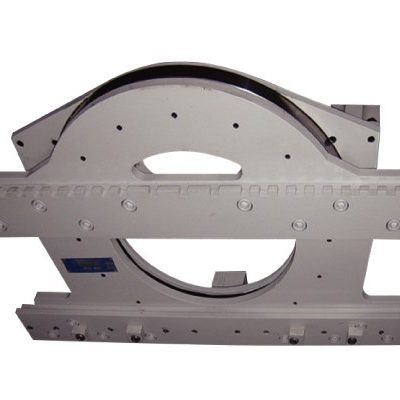

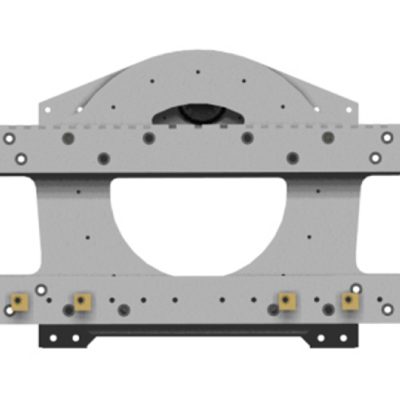

1. Makusog nga motor haydroliko nga Eaton.

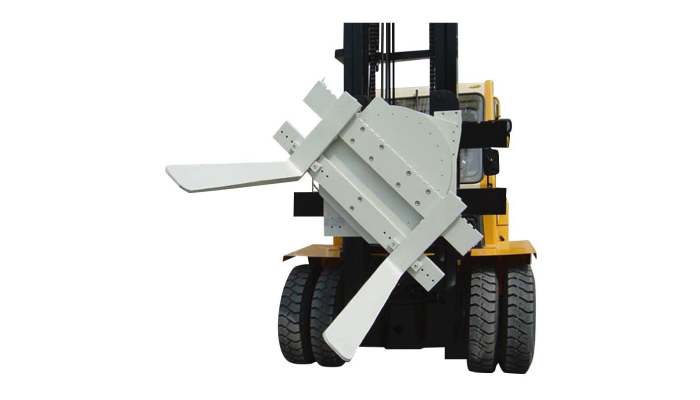

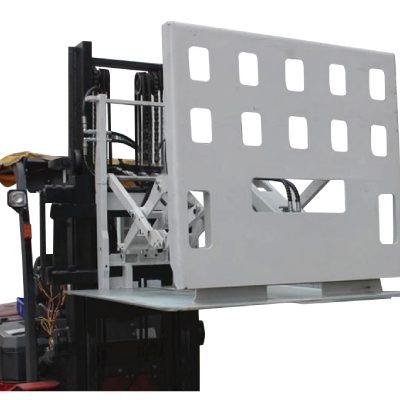

2. Ang Rotational Torque-Maayong torque nagsiguro sa hapsay ug positibo nga pagtuyok sa luwan.

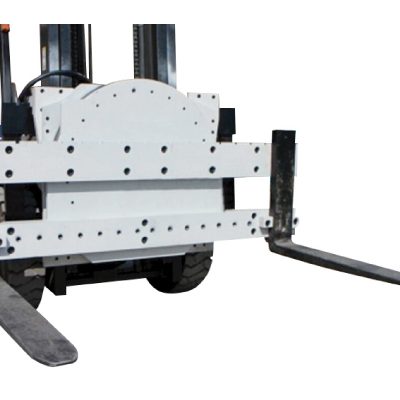

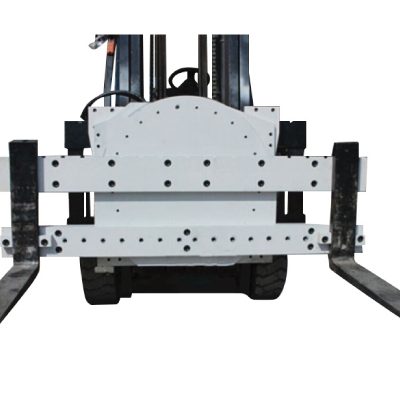

3. Ang drive box ug motor nakabutang sa luyo sa baseplate aron mahatagan ang maximum nga panan-aw alang sa driver sa forklift.

4. Ang mabug-at nga katungdanan nga gearbox ug rotating bearing naghatag labing maayong kinabuhi sa serbisyo.

5.1 usa ka piraso sa trak nga auxiliary nga kinahanglanon. 140bar≤ Working Pressure ≤ 180bar.

6. Fitting Screw M18X1.5-74 ° (concave); Girekomenda nga Hydraulic Pipe internal diameter = 10mm (3/8 '').

7. Kung wala’y gihangyo, ang mga Rotator gipadala nga wala’y mga tinidor!

Mga Video

| Sentro nga kapabilidad @ Mag-load | Modelo | Klase | Pagdagan Lapad (B) (mm) | Fork Max.Spacing (mm) | CGV (mm) | CGH (mm) | ET (mm) | Serbisyo Gibug-aton (kg) |

| 1600@500 | RT-25M-A01 | 2 | 970 | 860 | 312 | 65 | 132 | 181 |

| 1600@500 | RT-25M-A02 | 2 | 1040 | 930 | 310 | 65 | 132 | 290 |

| 2500@500 | RT-25M-A11 | 2 | 1040 | 930 | 262 | 86 | 170 | 290 |

| 2500@500 | RT-25M-A12 | 2 | 1100 | 990 | 262 | 90 | 170 | 297 |

| 3500@500 | RT-35M-B01 | 3 | 1100 | 990 | 285 | 122 | 248 | 310 |

| 3500@500 | RT-35M-B02 | 3 | 1200 | 1090 | 285 | 128 | 248 | 317 |

| 4500@500 | RT-50M-B01 | 3 | 1200 | 1090 | 285 | 126 | 248 | 320 |

| 4500@500 | RT-50M-B02 | 3 | 1380 | 1260 | 285 | 132 | 248 | 337 |

| 5400@600 | RT-70M-C01 | 4 | 1200 | 1090 | 372 | 115 | 275 | 570 |

| 5400@600 | RT-70M-C02 | 4 | 1535 | 1420 | 372 | 118 | 275 | 615 |

Batakang Impormasyon

Modelo NO.: RT-25M RT-35M RT-50M RT-70

Estilo: Usa ka nawong

Type: Pagdumala sa Materyal

Gahum: Forklift Attachment

Pagtino: Ec, ISO

HS Code: 843120

Materyal: Asero

Pagmaneho: Hydraulic Motor

Pag-load sa Kapasidad: 1 ~ 10t

Timaan: MIK

Sinugdanan: China

When purchasing a forklift rotator attachment, it is important to consider the following factors:

Compatibility: Make sure the rotator attachment is compatible with your forklift model and capacity.

Type of rotator: Choose the type of rotator that best fits your material handling needs.

Quality and durability: Look for a rotator attachment that is made with high-quality materials and is designed to last.

Customer service and support: Choose a supplier that offers good customer service and support, in case you need help with installation or maintenance.

It is also a good idea to read reviews and do research on the different types of forklift rotator attachments available, to get a better idea of what each one offers and what might work best for your needs.

In conclusion, purchasing a forklift rotator attachment is a smart investment for companies that handle heavy loads on a regular basis. It can help to increase efficiency, reduce the risk of injury and damage, and save time and money in the long run.